SANITATION DISTRICT - WILLIAMSBURG, VAOptimum odor control and operating costs were achieved by maximizing the chemical energy in sodium hypochlorite with an innovative automated control system. |

||||

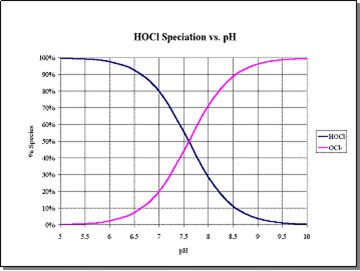

PROBLEM:This project required a scrubbing system that would treat strongly odorous foul air that contained compounds which are not responsive to conventional wet scrubbing with sodium hypochlorite. The site conditions and other variables also ruled out biological remediation, thermal oxidation etc. SOLUTION:Pacific Rim was contracted to create a scrubbing environment that would encourage sodium hypochlorite to express its seldom used but much stronger oxidation potential. It is typically avoided because that type scrubbing environment is difficult to control. Pacific Rim developed a reliable process control strategy that maintained the stronger oxidization potential of sodium hypochlorite and effectively destroyed the tough to scrub organic sulfur compounds. The significance of this automated control breakthrough is best understood if the chemistry involved is explained. In water, sodium hypochlorite speciates into hypochlorous acid (HOCl) and hypochlorite ion (OCl -). The ratio of each in a solution is determined by the pH of the solution. Hypochlorous acid is the stronger oxidant of the two and is therefore desired in a solution used to scrub odorous organic and sulfide compounds that are resistant to oxidation. If oxidation strength was the only variable to consider in scrubber design, the typical scrubber using sodium hypochlorite would operate at a pH far below 7 where hypochlorous acid is present in large quantities. In practice this is seldom done because odorous air typically contains more than one target compound, and each compound in the mix tends to be optimally scrubbed in its own unique chemical environment. This diversity necessitates the creation of a scrubbing environment that is a compromise but still conducive to the destruction of the majority of the odorous compounds present in the odor mix. At a low scrubbing solution pH (the environment that optimizes the HOCl concentration), the scrubber does not readily remove other odorous acidic compounds hydrogen sulfide from the foul air. Therefore to successfully address both the tough to scrub organic sulfides and the acidic sulfides in the foul air stream, we need a scrubbing environment with a pH as high as possible without dramatically reducing the concentration of HOCl. Our target pH 7.0. This is a good compromise from a chemistry perspective, but creates an enormous challenge for process control. Easy process control occurs when a large change in the reaction environment (pH) produces a gradual change in the concentration of the variable being controlled. The graph above displays this condition at pH ranges above 9 and below 6. In these areas of the graph we see a very flat slope that represents minimal change in speciation per unit of pH change. Unfortunately the graph displays quite the opposite condition near pH 7. Near 7 we see the graphs lines are relatively steep and this represents a dramatic change in speciation over a narrow change in pH and that means the process is difficult to control. Fortunately, Pacific Rim and AEC found a way to control the reaction environment in this precarious pH range, thereby providing the optimized scrubbing environment for acidic and difficult to scrub odorous compounds in a wastewater (or equal) foul air stream. This is just one of many proprietary process methodologies available from Pacific Rim to optimize a scrubbing environment to your specific requirements. The Williamsburg design optimized the chemical usage and scrubber efficiency by operating each of the two stages at a different pH range. This allowed the first stage to oxidize the tougher compounds and use the second stage to re-capture excess oxidants to save chemical cost. The second stage with a higher pH also captured any stray acidic sulfide compounds. This process can both effectively scrub challenging odorous compounds and operate in a cost effective manner. |

Overall view of three each two stage scrubbers.

Graph 1

View of chemical metering pump room supplying chemicals to the six individual scrubbing stages . The AEC controllers operate all of this equipment.

AEC controller for the scrubbing system.

|

|||

| All Text ©Copyright 2008 Pacific Rim Design & Development, Inc. | ||||