Environmental Compliance Can Be Profitable

Robert Richardson Ph.D.

Environmental compliance is a necessity, but it does not need to be expensive and in some cases it can even be profitable. For example, industries that meet the requirement outlined below can use a process now available that removes essentially all NOx and SO2 and thus makes available a large number of Emission Reduction Credits (ERCs). These can be sold.

A process now available removes essentially all NOx and SO2 and thus makes available a large number of Emission Reduction Credits (ERCs). These can be sold.

This article describes how to profit from economic incentives associated with environmental abatement in excess of that required by regulatory agencies.

The formula for profitable environmental compliance is simple. Combine one each of the following:

- Large source of criteria air pollutants that is locally regulated by the Environmental Protection Agency (EPA)

- Availability of environmental credits with an economical price per weight for the regulated pollutants (California and Texas areas are good candidates.)

- Availability of an environmental abatement technology that can cost effectively remove considerably more than the required amount of the regulated pollutant.

Combining the three requisite components does require skill because there are many details and intricacies surrounding the successful integration in a way that maximizes profitability. An example is the following:

- Environmental credits that are the core of profitability could be integrated into other environmental programs like cap-and-trade and emission trading. Fortunately, the options are concise and professionals are available to provide guidance in this area of complexity.

- It is essential that the source emitting the criteria pollutants is affiliated with a geographic area that offers credits for the destruction of the pollutants. Ideally the source is located within the geographical area, but there are exceptions that should be considered. This match is relatively easy to verify.

- The methodology selected to abate the criteria pollutant must be able to dramatically reduce the concentration of the pollutant below the local regulatory agency’s performance threshold in a cost-effective way. This requirement can be the most difficult to meet because most abatement technologies deliver linear improvements in removal efficiency at exponentially increased costs once the technologies exceed their typical performance capabilities .

The six common criteria air pollutants are ozone (O3), particulate matter (PM), carbon monoxide (CO), nitrogen oxides (NOx: both NO and NO2), sulfur dioxide (SO2), volatile organic compounds (VOC’s), and lead (Pb) .

Regulatory compliance requirements vary by geographic area. The EPA requires each state with a pollution problem to file a State Implementation Plan. The states then require local agencies within the state to file their own compliance plans to meet even more localized compliance challenges. As noted above, successful application of the profitable environmental compliance formula requires a match between a local regulatory compliance requirement for a specific criteria pollutant and the emission of that pollutant at a facility typically within the jurisdiction of that regulatory agency.

When the pieces come together, the results can be profound. The following is an example.

PILKINGTON GLASS EXAMPLE

A Pilkington Glass facility at Lathrop, California (within the San Joaquin Valley Unified Air Pollution Control District [SJVUAPCD] regulatory district) asked Pacific Rim Design & Development (PRDD) to propose a solution that would meet or exceed the local regulatory agency requirements for NOx, SO2, and particulate generated by a large natural gas-fired furnace. PRDD designed and then successfully pilot-tested a combination of abatement technologies at the Pilkington facility. The pilot study performance results demonstrated removal efficiencies that removed virtually all NO, NO2, and SO2—an amount that dramatically exceeded the SJVUAPCD requirement for abatement of these criteria pollutants. The PRDD technology also removed more than the requisite amount of particulate.

Thus a large number of credits are available, which may be sold on the open market.

Baseline source data for Pilkington facility

(Available from SJVUAPCD)

- Pilkington plant makes approximately 75,000 standard cubic feet per minute of exhaust gas.

- Gas temperature at base of stack is approximately1000°F.

- Gas contains 130–150 pounds NOx per hour (Mostly NO).

- Gas contains 15–40 pounds per hour of SOx.

- Gas contains 10–13 pounds of particulate per hour.

- Plant production is 500–550 tons of glass per day.

- Plant operation is 24 hours per day.

Baseline SJVUAPCD Rule 4354 (compliance requirements):

- Table 1 Tier 4 = 2.9 pounds NOx (measured as NO2) per ton of glass produced per day

- Table 3 = 1.2 pounds SOx per ton of glass produced per day

- Table 4 = 0.7 pounds PM10 per ton of glass produced per day

Removal efficiency of abatement system:

- 99.9 percent removal efficiency for NO, NO2 and SO2

- 89.5 percent removal efficiency for PM10

How much added profit was potentially available from reducing NOx & SO2 to nearly zero?

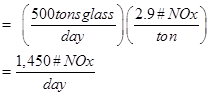

SJVUAPCD Rule 4354 -Table 1 Tier 4 = 2.9 pounds NOx (measured as NO2) per ton

Maximum NOx allowed:

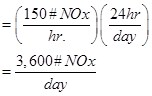

Source (Pilkington) untreated NOx emission:

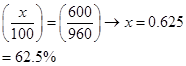

Solve for percent NOx removal efficiency required to minimally meet regulatory requirement.

![]()

![]()

Solve for percent excess NOx removal efficiency. If this can be economically removed, the value of the credits for removing this excess NOx can be sold by Pilkington

![]()

Tons of NOx available to be reduced:

![]()

________________________

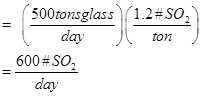

SJVUAPCD Rule 4354 – Table 3 = 1.2 pounds SOx per ton of glass produced per day

Following the same computational approach for NOx, the maximum SO2 allowed:

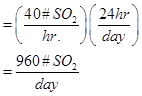

Source (Pilkington) untreated SO2 emission:

Solve for percent SO2removal efficiency required to minimally meet regulatory requirement.

Solve for percent excess SO2 removal efficiency

![]()

This is the amount of SO2 in excess of the required SO2 removal requirement. It can be sold for credits if a way to economically remove it can be found.

Tons of SO2 available to be reduced:

![]()

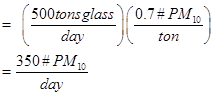

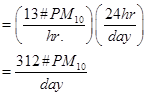

SJVUAPCD Rule 4354 – Table 4 = 0.7 pounds PM10 per ton of glass produced per day

Maximum PM10 allowed:

Source (Pilkington) untreated PM10 emission:

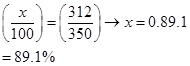

Solve for percent PM10 removal efficiency required to minimally meet regulatory requirement.

_____________________________

Solve for percent excess PM10 removal efficiency is available for sale

Tons of PM10 available for Emission Credit Sale:

![]()

________________________

How much potential income is generated by using an efficient abatement system?

(The following numbers were not confirmed by Pilkington)

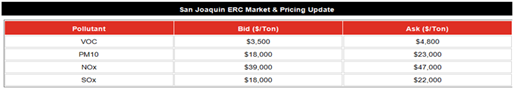

Brokers like BGC buy and sell ERCs generated by environmental compliance that is in excess of agency requirements. The values for emission credits fluctuate on an open market much like the stock market.

In June 2013, when the original emission credit evaluation was made for the Pilkington project, the values offered by BGC were as shown in Exhibit 1:

The calculations below are based on the average between the bid and ask price.

NOx = $43,000 per ton

SO2 = $20,000 per ton

PM10= $20,500 per ton

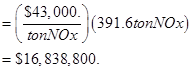

Estimated proceeds from sale of excess NOx credits:

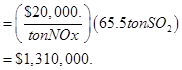

Estimated proceeds from sale of excess SO2 credits:

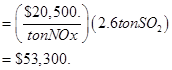

Estimated value of excess PM10 credits:

Total estimated value of available excess emission credits:

![]()

How much potential profit was available as a result of selecting a cost-effective abatement system?

PRDD, a licensed contractor and expert in abatement system design and fabrication, estimated the installed cost of abatement equipment required to produce the emission credits described above to be:

![]()

Theoretical profit estimated by PRDD:

![]()

IMPLICATIONS

The above is a real example of the economic potential power of this formula for profitable environmental compliance. The theoretical profit of this example is the result of an adroit combination of parameters:

- Quantity of NOx and SO2 that required abatement

- Efficiency and cost effectiveness of the abatement technology

- Exchange rate for NOx and SO2 credits

Each situation is different and not all projects produce a profit. This model is not limited to NOx and SO2; it also applies to the other regulated pollutants.

Typically, large industrial and utility projects have the propensity to meet the above requirements.

The identification of a cost-effective abatement system with high removal efficiency is the most challenging aspect of this equation. There are variables beyond the obvious equipment cost and removal efficiency. An often-overlooked variable is the cost of treating any waste products generated by the abatement process. In liquid abatement systems this can come from contaminated waste liquids. In gas- phase reactions like selective catalytic reduction more costs can come from creation of particulate that is itself a criteria pollutant.

An often-overlooked variable is the cost of treating any waste products generated by the abatement process.

Pacific Rim Design & Development and other firms focus on GREEN in the design of abatement technology. It is possible to have cost effective systems which produce little or no waste products. Some projects even generate reaction byproducts with commercial value. As an example, the Know-NOx process for NOx and SO2 abatement can produce commercially viable fertilizer (ammonium sulfate) and commercially viable mineral acids.

Robert Richardson, Ph.D., (robert@prdd.net) is president of Pacific Rim Design & Development Inc.